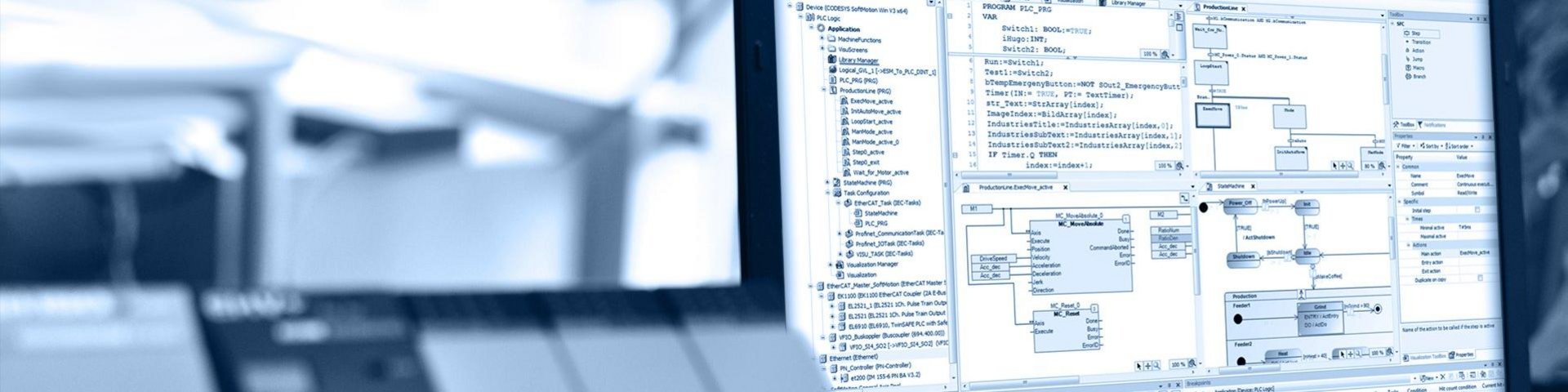

3D-CNC and robot control integrated in one IEC 61131-3 development system

With CODESYS SoftMotion CNC+Robotics, end users can engineer complex CNC tasks and robotic controllers without having to leave the IEC 61131-3 development system.

For CNC motion planning, a DIN 66025 compliant 3D CNC editor is available with G code. Geometric data, interpolation, and kinematic transformation are edited by means of library POUs. For this purpose, end users can access the entire range of services of the IEC 61131-3 compliant development system. CODESYS SoftMotion CNC+Robotics extends the functional scope of CODESYS SoftMotion with typical kinematics and a CNC interpolator.

Simplified project engineering of robotic kinematics

CODESYS SoftMotion CNC+Robotics provides end users with an easy-to-use integrated editor for configuring complex robot axis groups. In the editor, required kinematics can be selected, parameterized, and linked to the physical robot axes. Robotic functions are processed by means of standardized function blocks compliant with PLCopen® MotionControl Part 4.

Requirement

An implemented CODESYS Control SoftMotion CNC+Robotics runtime system on the motion controller (performed by the device manufacturer)

CNC

- 3D CNC editor according to DIN 66025 (G code) for motion planning and representation; with parallel textual and graphical display and DXF import

- CODESYS CNC library with all function blocks for CNC editing

- Sample application of 3D CNC motion with tutorial

- Comprehensive interpolation functions from linear to spline interpolation

- Functions for path processing, incl. tool radius compensation, loop suppression, and angle rounding

- Kinematic transformations for different systems, such as gantry, SCARA, and tripod robots

- Visualization templates for fast and easy commissioning of all function blocks in CODESYS Visualization

- Visualization element for online display and operation of 3D paths, for example as an operating unit in CNC machine tools

- Support of virtual and logical axes

- Integrated drivers for many CAN, CANopen®, and EtherCAT® drives

- Configuration of drives as safe field devices

Robotics

- Convenient parameterization of axis groups for predefined kinematics in a separate configurator

- Integrated motion planning with coordinate values for robot positions in different coordinate systems

- Function library with program blocks according to PLCopen Motion Part 4, such as MC_GroupEnable/Disable/Reset/ReadError, MC_MoveDirectAbsolute, MC_MoveDirectRelative, MC_GroupHalt, MC_GroupStop, MC_TrackConveyorBelt, and MC_TrackRotaryTable

- Numerous supported kinematics with convenient configuration, for example various gantry robots (2/3/5 axes), bipod/tripod robots, and SCARA robots

- Additional orientation kinematics

- Support of tools with orientation and position offset (full 6D)

- Support for user provided dynamic models that compute the torques and forces for each joint

- Support for torque/force limitation during planning

- Support for torque/force feed forward control

- Support for defining the workpiece and tool load

- Trigger points

- For more information, refer to the data sheet for CODESYS SoftMotion CNC+Robotics in the CODESYS Store.

- Overview of the supported drives

- Ideal supplement: CODESYS Depictor for the creation of 3D visualizations of complex CNC and robotics movements within the IEC 61131-3 application code.

As system integrator or end user for example in machine or plant construction:

Employ controllers that are already equipped with CODESYS SoftMotion CNC+Robotics. Millions of CODESYS-compatible single devices and over 1,000 different device types from more than 500 manufacturers offer you a large range of hardware for your automation projects. CODESYS Inside offers a selection of manufacturers that offer CODESYS-compatible devices. Or implement your own CNC or robot controller based on SoftPLC systems and use the CODESYS SoftMotion CNC+Robotics add-on option for licensing:

- CODESYS Control RTE SL

- CODESYS Control RTE SL (for Beckhoff CX)

- CODESYS Control for emPC-A/iMX6 SL

- CODESYS Control for PLCnext SL

As manufacturer of programmable devices:

Get the CODESYS SoftMotion runtime system toolkit with a CNC+Robotics device license and implement your specific CNC or robot controller with CODESYS SoftMotion CNC+Robotics. You can select the CPU platform and operating system for your motion control system from various platforms.

For consultation, products and services, and more information, contact sales @codesys.com.

CODESYS brochures and information material

|

CODESYS - One software. All applications. Your Automation Solution.

Version: 10/2023

|

pdf

2 MB

11.12.2024

|

|

|

CODESYS - One software. Any field of application. Your automation platform.

Version: 10/2023

|

pdf

2 MB

07.11.2023

|

|

|

Verschiedene Anbieter präsentieren CODESYS-kompatible Geräte und spannende Lösungen, die für Ihre Automatisierungsaufgaben nützlich sein können.

Version: 10/2024

|

pdf

2 MB

11.12.2024

|