Benefits for device manufacturers

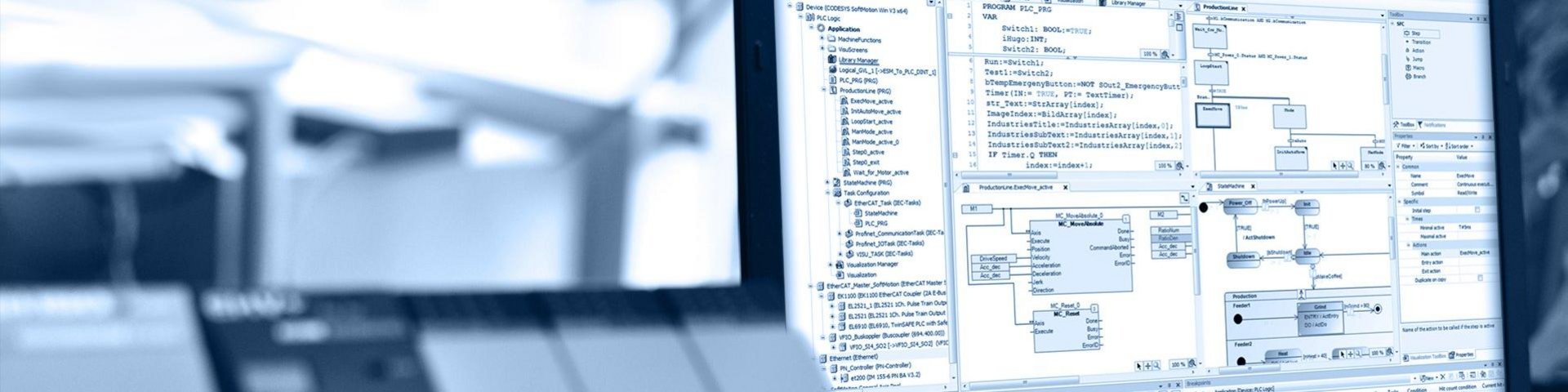

Realizing an intelligent automation device with calculatable expenses and high market acceptance: Manufacturers of intelligent components benefit from the extensive features of CODESYS in the development of their devices.

- Product available as a modular single-source runtime system for different device platforms

- Support for all common processors and operating systems for industrial systems, including native usage of multicore architectures (multicore support)

- Projectable development expenses: Development of industrial controllers with pronounced technical characteristics by means of defined interfaces and qualified adaptation support

- Numerous available reference systems and platforms (e.g. for popular Arm® Cortex® or embedded systems)

- Easy implementation of specific device properties by means of library modules (e.g. for own I/O functions)

- Adaptation and extendability of the user interface by manufacturer-specific plug-in modules (e.g. templates, editors, configurators, and wizards)

- Integration into existing system architectures by means of lean proprietary interfaces or standards, such as OPC / OPC UA

- Configuration of popular fieldbus systems, own I/O modules or drives (e.g. for CANopen®, EtherCAT®, or PROFINET)

- Integrated visualization available as optional extension: Generation and display of practice-oriented user interfaces, e.g. directly on the device display, with connected screens or via web browser

- Numerous optional add-on products for fast scaling of the functional scope of the device (e.g. as motion controller, panel control, or communication gateway)

- Pre-certified software products for extending the standard controller into a TÜV-certified safety controller compliant with IEC 61508 SIL2 or SIL3

- Configuration and project engineering of industry-specific communication protocols (e.g. for building services control systems with BACnet®)

- Optional interface for integrating existing or generated C code

Reliable partner for successful automation devices

- The CODESYS Group: Product development by expert engineers and computer scientists by means of a proven, agile development framework (Scrum)

- Practice-oriented support from experienced project developers in the development of automation devices — from the initial idea to its implementation and product maintenance

- Fast response times to market demands with market-ready products: e.g. extend existing logic controllers to be flexible CNC controllers, provide them with integrated OPC UA servers, implement automated device and applications tests or TÜV-certified safety controllers

- Reliable maintenance, care, and quality assurance of all products and features by means of practical processes, ISO 9001-certified (since 2005)

- Long-term and confidential cooperation with device manufacturers from different branches and regions

- Transparent management with distinctive communication culture (e.g. by means of regular coordinating meetings at different levels, direct access to database for product improvement and ideas)

- High market acceptance of CODESYS-compatible automation devices by means of wide distribution among tens of thousands of users worldwide

- Services for common product marketing (e.g. at trade fairs, events, and online)

Benefits for users

End users employ CODESYS for successful creation of simple and sophisticated automation applications for industrial controllers that are used in factories, mobile machines, power and building automation systems, as well as many other areas. Several features and properties of the system help in this work.

Everything is integrated in a single user interface

- Complete IEC 61131-3 programming system – from classic PLC programming to object-oriented controller programming

- Extensive features for convenient project engineering and commissioning of automation applications, such as data monitoring, scanning for application errors (debugging), and changing the application during operation (online change)

- Optional add-on modules for methodical application development: UML®, version management, static code analysis, profiling, and test automation

- Configuration and commissioning of the most important industrial fieldbus systems or manufacturer-specific I/O systems

- Seamless integration of optional add-on components for project engineering: Visualization, motion control / CNC / robotics, safety modules

- Installation, maintenance, and training required only for a single user interface: Minimization of engineering effort

- Extendable function range through additional products available in the online store and with on-board tools (programming of function or communication libraries in the IEC 61131-3 languages, for example)

- Easy connection to a convenient Industry 4.0 platform for managing control landscapes per cloud

Open selection for the next automation task

- Hundreds of automation devices from prestigious manufacturers programmable with the CODESYS Development System

- SoftPLC systems for standard platforms — available in the CODESYS Store

All popular fieldbus systems — with integrated configurators and generally also with protocol stacks - Access to tested add-on tools and application libraries — available in the CODESYS Store

- Easy linking in existing development environments and processes — optional customer and application-specific consulting

- Fast machine code for varyingly complex devices and applications, generated by industrially proven compilers

- Powerful tools for calculating 3D CNC / robotics, as well as 3D visualization (optionally integratable)

- Scalable functionality:

- Easy-to-use editors, e.g. FBD or LD

- Functional programming with many convenience functions

- Object-oriented programming with interfaces, methods, attributes, classes, inheritance, and dynamic linking in all IEC 61131-3 implementation languages

- Generic and specific I/O configurators

- Powerful add-on tools for methodical software development

- Fully developed concept for reuse and documentation of program code in libraries

- Add-on product for automated generation of complete control applications from preconfigured modules (optionally integratable)

Reliable and widely used system for established industrial applications

- Globally established system platform

- Over 10,000 application developers in the field

- Over 100,000 different applications

- Programming interface for approx. 1,000 different industrial controllers and over 1,000,000 devices sold every year

- Established use of CODESYS in applications with

- 50,000 OPC elements

- 25 MB application source code

- 800 MB PLC data

- Approx. 200 synchronized drives

- Widely used in educational institutions: For training future technicians and engineers in schools and universities

- Large global community of knowledge: Expert support for application development from third-party vendors, e.g. specially trained companies (CODESYS system partners) or independent programmers and consulting engineers, online forum for easy communication with other CODESYS users

- The CODESYS Group

Sets milestones in automation technology — either alone or in research projects with other automation companies and universities. As a member of standardization committees, the CODESYS Group makes sure that automation programmers benefit from progress (e.g. by taking advantage of current Internet technologies or innovations in information technology).

CODESYS brochures and information material

|

CODESYS - One software. All applications. Your Automation Solution.

Version: 10/2023

|

pdf

2 MB

11.12.2024

|

|

|

CODESYS - One software. Any field of application. Your automation platform.

Version: 10/2023

|

pdf

2 MB

07.11.2023

|

|

|

Verschiedene Anbieter präsentieren CODESYS-kompatible Geräte und spannende Lösungen, die für Ihre Automatisierungsaufgaben nützlich sein können.

Version: 10/2024

|

pdf

2 MB

11.12.2024

|