With the CODESYS Visualization an entire picker line simulation can be run on a single robot controller. The integrated offline simulation makes it possible to significantly increase the efficiency of packaging systems.

With the CODESYS Visualization an entire picker line simulation can be run on a single robot controller. The integrated offline simulation makes it possible to significantly increase the efficiency of packaging systems.

When handling or packaging consumer goods, especially food products, the production volume often requires using multiple robots. If several robots are processing a common product flow, this is typically referred to as picker line. A proper product handling is a prerequisite to successfully realize picker lines. The focus of the implementation typically lies on managing the product flow.

In the case at hand, a producer of consumer goods requests to feed 1160 products per minute to the packaging machine. As two products can be picked simultaneously, 580 pick-and-place operations per minute are required. The packaging machine manufacturer has cooperated with VELTRU as component supplier to offer the customer a system with five robots in counterflow configuration. Thus, each robot has to perform 116 strokes per minute on average.

In a counterflow configuration, the flows of products and of pockets to be filled are arranged in parallel and moving in opposite direction. The first robot always has products and must fill all remaining pockets. The last robot has to take all the remaining products, but always has empty pockets to load into. However, any deviation from a linear distribution of the product level within the system will lead to new disturbances, leading to waves in the product flow and resulting in alternating overcapacity and overload. Load Balancing is a control feature to manage such waves.

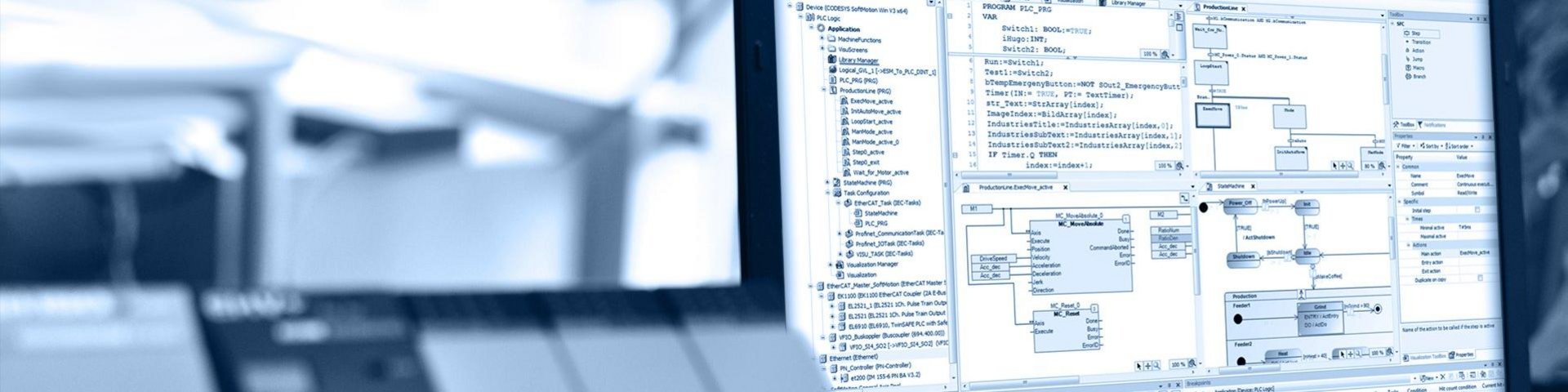

The commissioning of such systems in difficult, as only real production is able to deliver the required product volumes. But once in production, the pressure to finalize the delivery of the whole system is huge. VELTRU uses visualization elements for all of its software modules on both the C10 Robot Controller and the L10 Line Controller. The integrated CODESYS V3 Visualization makes it much easier to access the control data and create powerful visualizations of very dynamic processes. VELTRU has enhanced these possibilities to support the simulation of entire picker lines. For initial system design, a simplified application can be used. For the optimization of real picker line installations, all hardware components can be simulated and the line can be fully operated with the original software in simulation mode. This allows fast iteration cycles for the optimization process, with minimum costs. It is also possible to focus on error conditions. This results in an unprecedented optimization of the efficiency of picker lines and well-optimized load balancing settings.

For the respective simulation videos click here

More information on VELTRU under:

www.veltru.com

![[Translate to English:] Verpackungsmaschine

Roboterstraßen [Translate to English:] Pro Minute werden 1160 Produkte der Verpackungsmaschine zugeführen.

Leistungsfähige Visualisierungen um komplette Roboterstraßen in Simulation zu betreiben.](/fileadmin/_processed_/1/f/csm_AG_Veltru_Roboter1_1000_2b804b96ea.jpg)