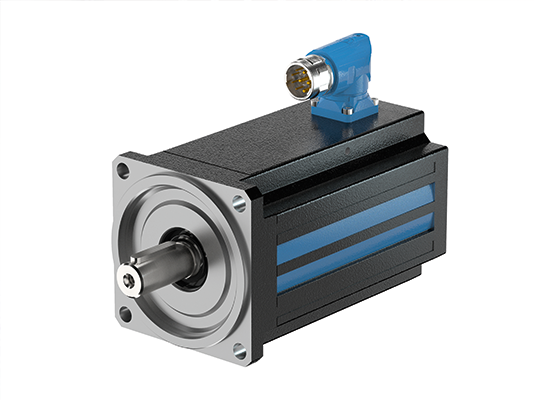

The rotors of the encoderless LeanMotor are manufactured at STÖBER in Pforzheim with the aid of a fully-automated robotic component mounting system. The central element is a rotary indexing table with five machining stations. With a total of three Scara robots, this table enables parallel processing at the individual stations.

The five machining stations are divided into the following processing steps:

Station 1:

- Scara 1 picks up the empty blank from one of the three places on the infeed conveyor.

- Rotative alignment via a sensor station and mounting on a mandrel on the rotary indexing table

- If the rotary indexing table already contains finished products, these are placed on a discharge conveyor so that the mandrel is free.

Station 2:

- Collecting the format-dependent number of magnets

- Pick & Place of the magnets into the round blank with Scara 2

Station 3:

- Pressing down of all magnets

Station 4:

- Scara 3 applies a glue bead with a linear path movement.

- Insertion of the magnets into the blank

Station 5:

- Exposure of the glue with a UV lamp

Clip of the application »

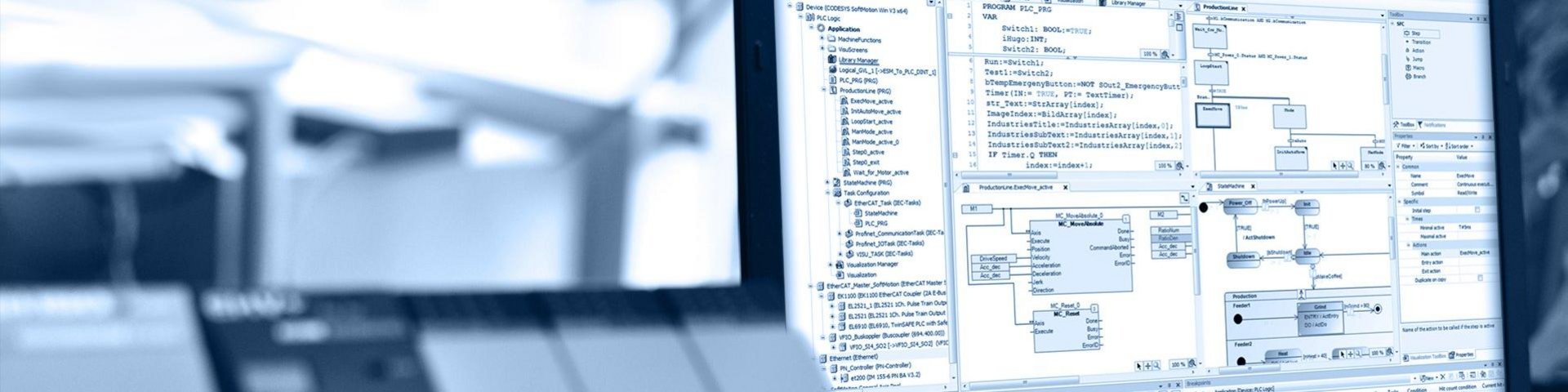

Controller: STÖBER MC6 (CODESYS RTE, SoftMotion CNC & Robotics)

Visualization: integrated CODESYS Target and Web Visu

Features: User management, alarm management, format management, multilanguage

Drives: STÖBER SI6 with PS6 16 SoftMotion axes in 8 double-axis modules,

Total width incl. supply module: 40.5 cm in the control cabinet

More information on STÖBER Antriebstechnik GmbH + Co. KG at: www.stoeber.de